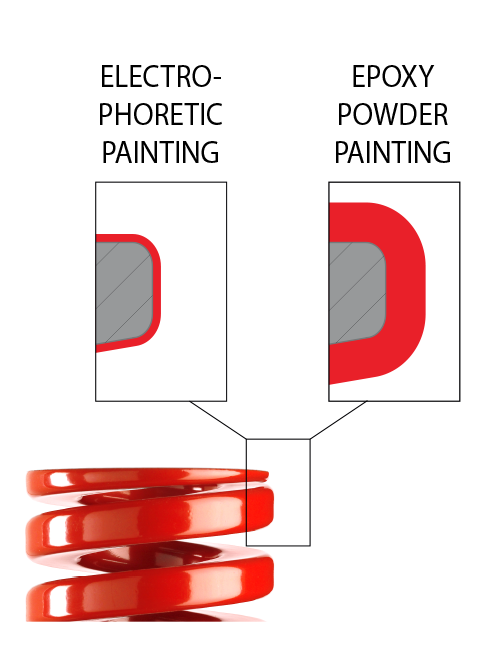

Electrophoretic Painting

NEW

Electrophoretic painting

Electrophoretic painting is a process where a metal part is immersed in a water-based solution and an electrical current is passed through the bath for coating the part.

OLD

Epoxy powder painting

Epoxy Powder Painting is a spraying painting method in which the coating powder is applied electrostatically.

BENEFITS

COATING THICKNESS:THIN

NEW

Electrophoretic painting

The coating’s thickness is accurately controlled with values ranging from 10 to 30 µm max. Thanks to thinner thickness the coating does not peel off when subjected to mechanical stress.

OLD

Epoxy powder painting

The coating’s thickness with values ranging from 70 to 100 µm can NOT be controlled. The higher thickness causes easy peel off coating when subjected to mechanical stress.

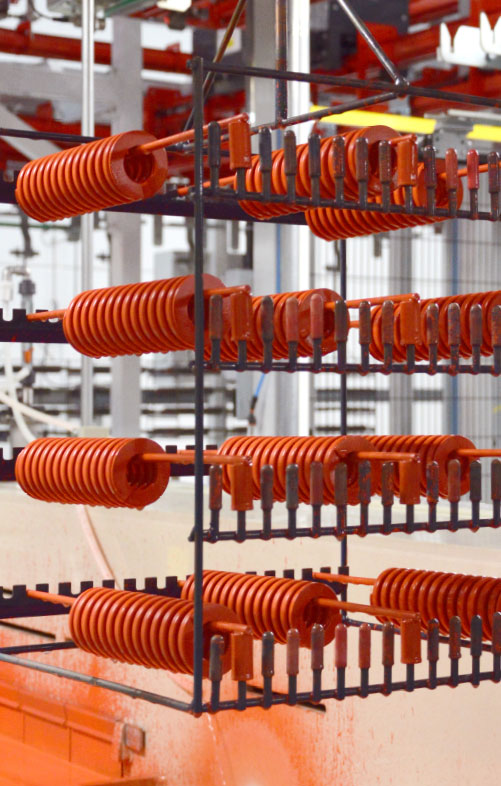

COATING COVER:100%

NEW

Electrophoretic painting

Electrophoretic painting covers with a uniform coating the whole surface, edges included, of any object, also with complex geometries. Dripping problems, possible with other painting methods, are NOT present. Die springs’ coating is complete and uniform.

OLD

Epoxy powder painting

Powder painting can NOT reach the die springs’ internal parts easily. Coating thickness is higher on the outside and lower or even absent on the inside of die springs. Die springs’ coating thickness is definitely NOT uniform.

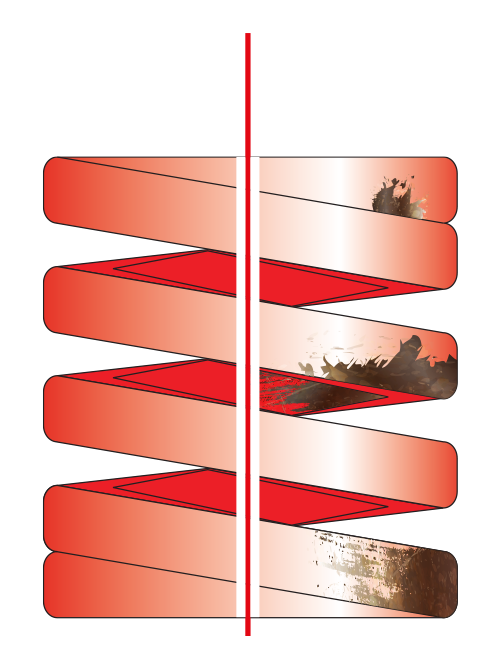

CORROSION RESISTANCE: HIGH

NEW

Electrophoretic painting

The presence of a cross-linked polyurethane chemical bond offers an excellent resistance to salt spray. This feature is enhanced through a uniform covering and thickness also of the inner surface of die springs.

OLD

Epoxy powder painting

While having inherent resistance and strength features thanks to their higher thickness, powder offer yet less protection to corrosion of the die spring as a whole because it can’t enter effectively internal part. Thus, less corrosion resistance due to the lower or even absent covering inside the die spring.

MECHANICAL STRENGTH: 100%

NEW

Electrophoretic painting

Given the lower thickness, the electrophoretic coating is as a result much more elastic. Higher mechanical strength is guaranteed.

OLD

Epoxy powder painting

Powder painting is featured with high thickness, thus bringing together more rigidity and weakness to the coating. This will result with lower mechanical strength.